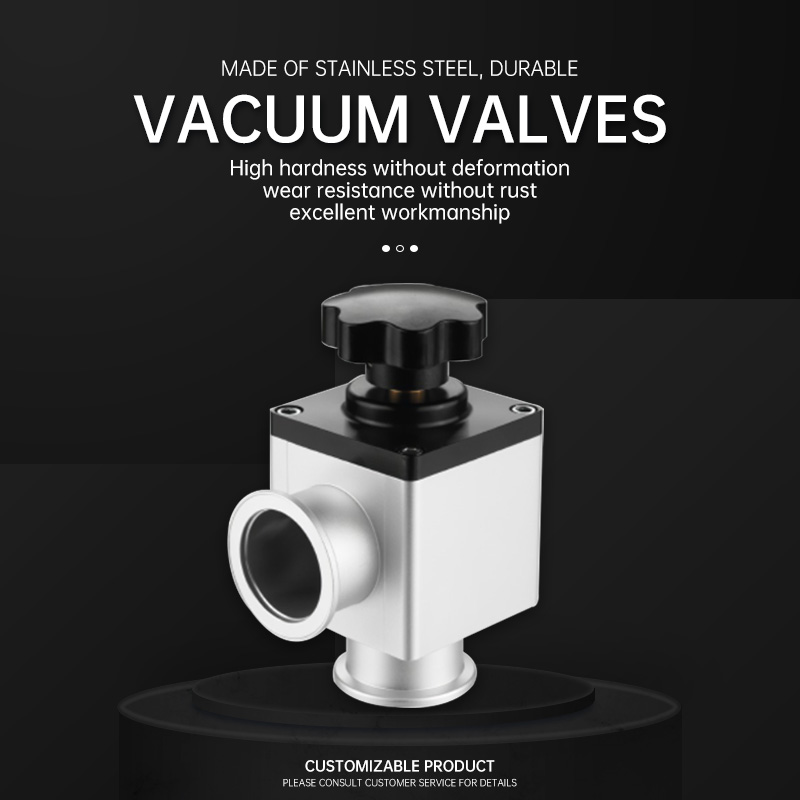

Vacuum Valve

2023-02-09

2023-02-09

Purpose of vacuum valve:

The electromagnetic vacuum charging valve and the electromagnetic vacuum differential pressure valve are vacuum valves specially used to prevent oil return from the mechanical vacuum pump. They are installed at the air inlet of the mechanical vacuum pump and are opened and closed synchronously with the pump. Generally, it cannot be used in other places, that is to say, it cannot be used for venting in the vacuum system. The advantage of using Niwei electromagnetic vacuum differential pressure valve is that the power consumption is very small and energy is saved; The valve body with DN ≤ 50 is made of aluminum alloy, which is light in weight, small in size and fast in closing.

The flapper valve is used in the corner and tee of the vacuum pipeline. The driving modes are manual, pneumatic, electromagnetic and electric, which are determined by the user. Among them, GDC-J electromagnetic high vacuum flapper valve is a metal bellows seal, which has a wide range of applications and can also be used as an air charging valve; The installation position can be arbitrary, and the pressure can be reversed to one atmosphere, with feedback signal output.

The gate valve is used in the situation where the vacuum degree is high or the pipe size is high. Full conduction, valve leakage rate is 10-7Pa L/S, double sealing. The driving mode is determined by the user. Both pneumatic and electric devices are equipped with signal feedback devices.

Diaphragm valve and ball valve are straight through type and can be used in situations where positive pressure and vacuum coexist. The driving mode is determined by the user.

The butterfly valve is a straight through type, and the manual, pneumatic and electric drive modes are determined by the user. The opening angle of manual butterfly valve can be adjusted at will; The opening angle of intelligent pneumatic and electric butterfly valves can be adjusted at will.

Service conditions of valves:

1. The medium is pure air or non corrosive gas.

2. The medium temperature is determined by the extreme temperature of rubber.

Vacuum valve refers to the vacuum system element used in the vacuum system to change the air flow direction, adjust the air flow, and cut off or connect the pipeline. The closing element of vacuum valve is sealed with rubber sealing ring or metal sealing ring.

The bellows of the bellows stop valve is made of stainless steel, high zinc brass JI80, plastic and other materials. Diaphragm seals can be used for shut-off parts of stop valves with small diameters (diameters below 10 mm). Ball cock valves can be used for low and medium vacuum.

Xi'an Borusco Vacuum Technology Co., Ltd. was established on December 26, 2017 with a registered capital of 8.6 million yuan. It is located in Xi'an High-tech Industrial Park, the ancient capital of China. It is a company specializing in various domestic and foreign vacuum pumps, molecular pumps, vacuum accessories, vacuum measurement, leak detection equipment, vacuum seals and vacuum pump oil, vacuum exhaust tables, and space environment simulation devices; it integrates vacuum equipment leak detection, vacuum system A high-tech industrial company integrating design, processing, sales, technical after-sales, and maintenance services.

The company mainly produces 600-1600L compound type; 3600L turbine type; 300L, 650L, 1300L, 2000L grease lubrication and other ultra-high vacuum acquisition equipment - molecular pumps, ultra-high vacuum baffle valves of various specifications, ultra-high vacuum units, etc. The company's products are constantly innovating and introducing new products, which are at an excellent level among similar products in China.

The company's related molecular pump products can obtain clean high vacuum and ultra-high vacuum, which are widely used in various fields of vacuum technology such as photovoltaic, lighting, aerospace, semiconductor, energy, military, laser, home appliances, materials, and automobiles. Borusco Vacuum Mainly produces 600, 1200, 1600 L compound type; 3600L turbine type; 300L, 650L, 1300L, 2000L grease lubrication and other ultra-high vacuum obtaining equipment---molecular pump, various specifications of ultra-high vacuum flapper valve and ultra-high vacuum unit , Molecular pump control power supply, etc. The company's products are constantly innovating, ranking the leading level among similar products in China. Customers are located in various regions of China, and the application of molecular pumps in South Korea, Japan, the United States, Iran, India, Taiwan and other countries and regions is also expanding.

Contact Person:Tian Lei

Email:sxblskzhenkong@163.com

Newest

-

Dreame Pens a ‘Love Letter to the World’ with Spring Festival Gala Partnership and Times Square Debut

-

Chinese humanoid robots gallop towards consumer market

-

CYCJET: Providing innovative marking solutions for industrial intelligence along the Belt and Road Initiative.

-

Celebrating in the Sky: China Eastern Airlines to Offer Free In-Flight Wi-Fi as Part of Chinese New Year Connectivity Upgrade