What is low pressure injection molding process and what are the benefits

2020-10-13

2020-10-13

What is low pressure injection molding process?

Low pressure injection molding (LPM) is different from traditional injection molding. Low pressure injection molding is where parts are molded under lower pressure, allowing gentle packaging of precision electronic components. The secondary molding process involves loading the bare, unprotected PCB and cable assembly into a precision-made moldset tool, and then filling the cavity with appropriate low-pressure molding materials. This effectively encloses the components in the desired shape, producing a sealed and protected product that can be processed and tested immediately. The LPM process is very suitable to replace the epoxy potting process to save cycle time and reduce material consumption.

What are the benefits of low pressure molding?

The processing temperature and pressure required by traditional injection molding materials can damage printed circuit boards. Low-pressure molding (LPM) uses thermoplastic materials with very low viscosity, allowing even the most sensitive circuit board components to be re-molded and packaged. Because this material is a natural adhesive, this process is very suitable for sealing circuits against dust and moisture. The low-pressure injection molding process is very suitable for encapsulating precision instruments, such as circuit boards, data lines, automotive electronics, and sensors. , Micro switches, inductors, antennas and other precision components.

Newest

-

CYCJET: Providing innovative marking solutions for industrial intelligence along the Belt and Road Initiative.

-

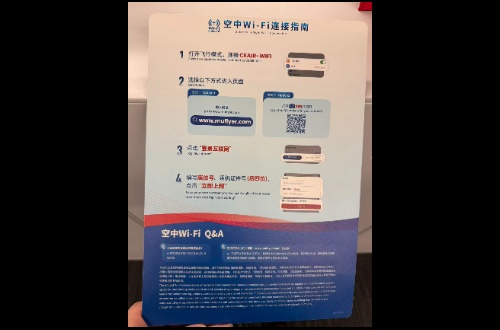

Celebrating in the Sky: China Eastern Airlines to Offer Free In-Flight Wi-Fi as Part of Chinese New Year Connectivity Upgrade

-

China Eastern Airlines Unveils Top International and Regional Destinations as Chinese New Year Travel Peaks

-

MEXC COO Vugar Usi on Navigating Crypto's 2026 Reset: Why Retail-First Exchanges Are Winning